Lỗi định dạng email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Tin tức

Ở đây, bạn có thể mô tả một đoạn văn bản bạn muốn diễn đạt.

Sự khác biệt giữa các tay cầm nha khoa tốc độ cao và tốc độ thấp là gì?

Các tay cầm nha khoa - thường được gọi là cuộc tập trận của người Hồi giáo - là một công cụ thiết yếu trong tất cả các thực hành nha khoa. Một loạt các chuyên gia nha khoa, vệ sinh, các chuyên gia về sức khỏe răng miệng và các kỹ thuật viên phòng thí nghiệm sử dụng các thiết bị được thiết kế đặc biệt này để hỗ trợ tối ưu hóa sức khỏe răng miệng của bệnh nhân trên toàn thế giới. Không có vấn đề gì nếu đó là một cuộc hẹn tiên tri tiêu chuẩn hoặc điều trị phẫu thuật toàn diện đang được tiến hành, các tay cầm nha khoa được sử dụng. Trong hướng dẫn cơ bản này, chúng tôi sẽ phác thảo những khác biệt độc đáo giữa tay cầm nha khoa tốc độ cao và tay cầm nha khoa tốc độ thấp.

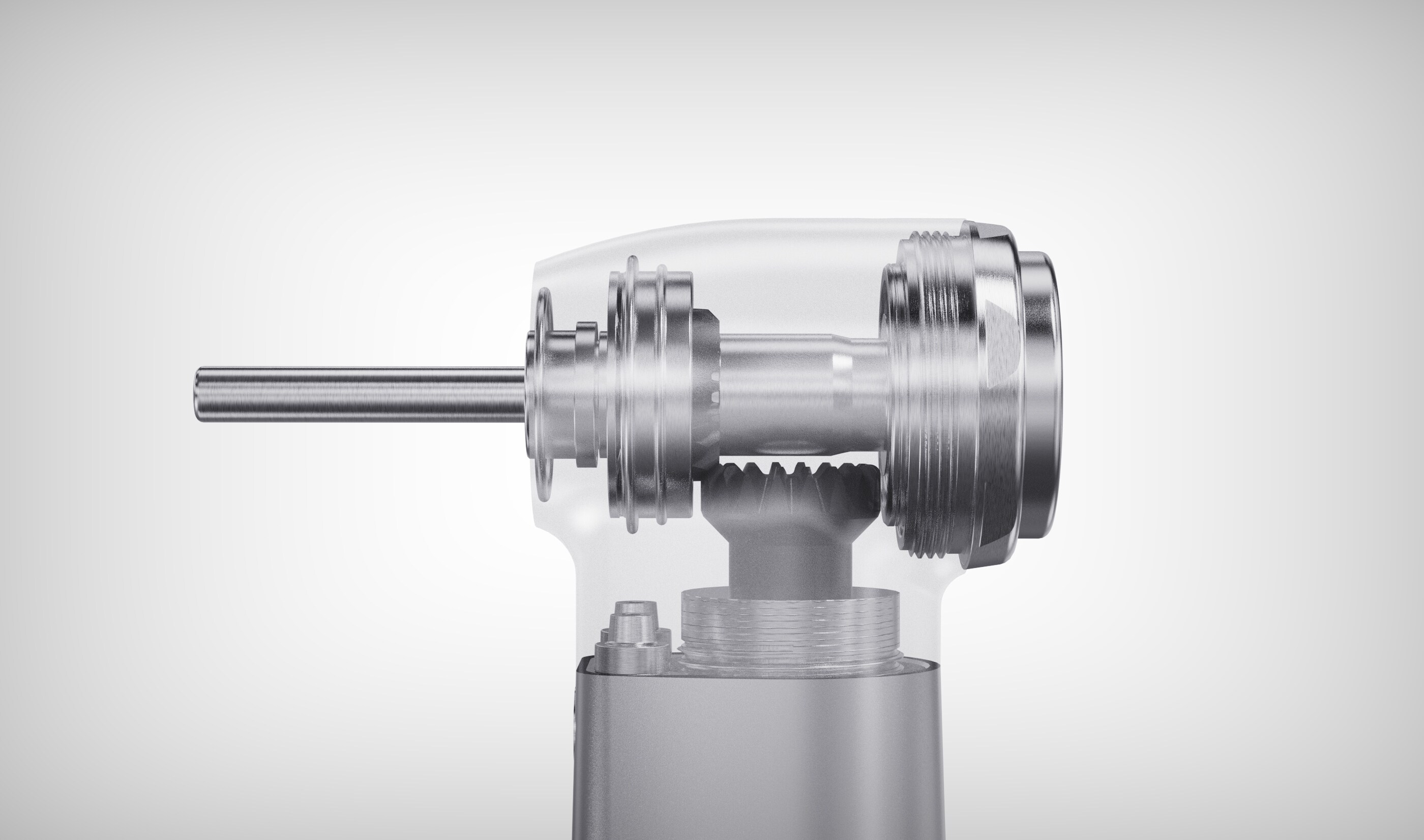

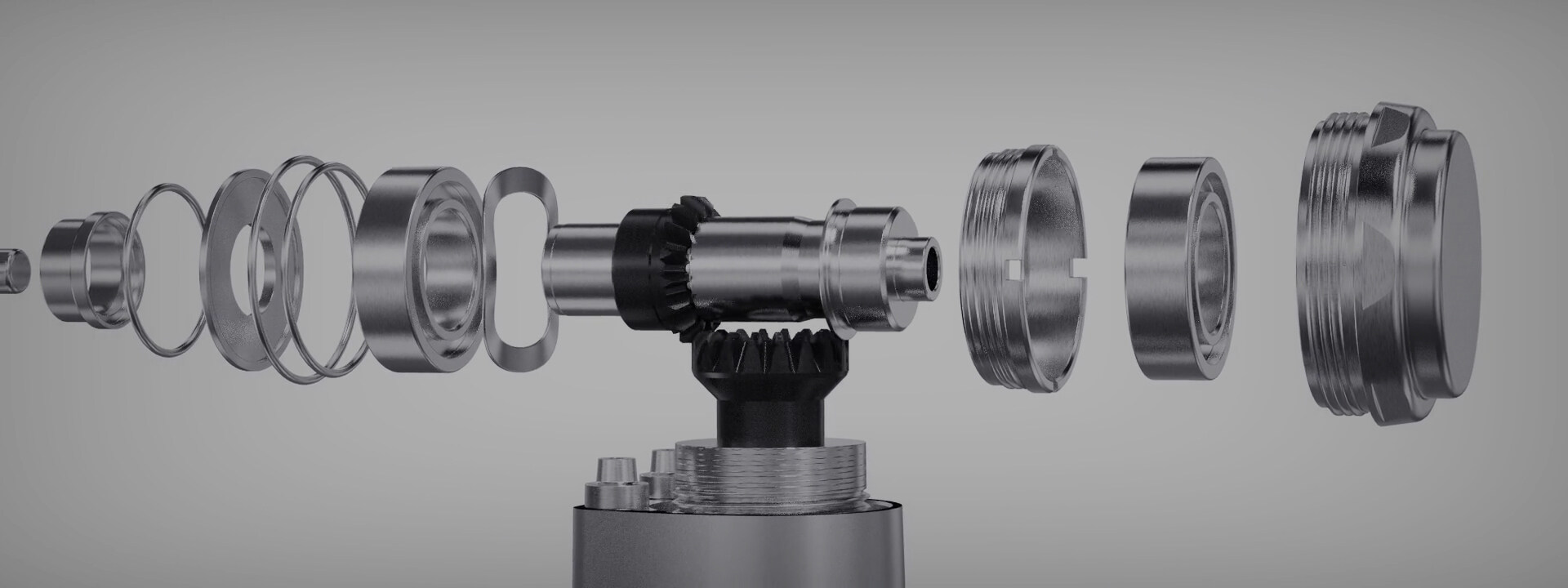

Một tay cầm nha khoa tốc độ cao là gì?

Một tay cầm nha khoa tốc độ cao được coi là một thiết bị có độ chính xác. Nó loại bỏ mô răng một cách nhanh chóng và hiệu quả cao. Nó không dẫn đến nhiệt, tăng áp lực hoặc rung động. Chúng có sẵn trong một loại hình dạng, kích cỡ và xây dựng chung. Hoạt động xảy ra ở mức 250.000 đến 400.000 vòng / phút. Các tính năng khác nhau cho vay để phân biệt của họ.

Ví dụ về các tính năng này bao gồm loại gắn đầu, kích thước của đầu, nguồn ánh sáng, trọng lượng của mảnh và nhiễu của động cơ khi hoạt động. Chúng thường được sử dụng để đánh bóng răng và hình dạng thực tế của vương miện và trám.

Một tay cầm nha khoa tốc độ thấp là gì?

Các tay cầm tốc độ thấp cũng được coi là công cụ chính xác cho các bác sĩ và chuyên gia nha khoa. Chúng thường hoạt động với tốc độ 5.000 đến 40.000 vòng / phút. Lưu thông nước là không cần thiết vì các phiên bản tốc độ thấp không hoạt động ở mức độ mà chúng tạo ra nhiệt độ cao. Trong hầu hết các trường hợp, chúng được sử dụng cho các công việc nặng nề.

Các ví dụ bao gồm loại bỏ các hốc ra khỏi miệng và chuẩn bị răng cho việc bổ sung vương miện, veneers và/hoặc trám. Đây là những công cụ lý tưởng cho các thủ tục chỉnh nha và công việc phục hồi.

Do tốc độ hoạt động thấp, những tay cầm nha khoa này có xu hướng có tuổi thọ dài hơn so với các tay cầm nha khoa tốc độ cao. Điều này là do số lượng biến dạng ít hơn đối với các khía cạnh cơ học của thiết bị.